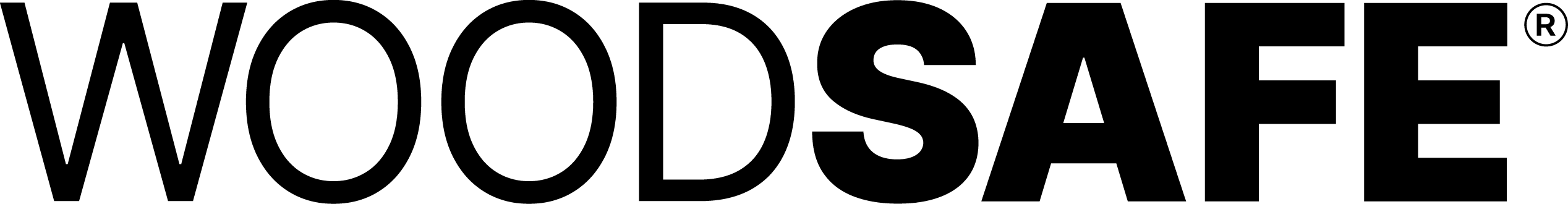

Our business

Our business is 100% fire impregnation

Building with wood is nothing new, it has been done for generations all over the world. But building new communities where tall, wide and complex wooden buildings are emerging at an ever faster pace is new and requires expertise and technical solutions against fire.

Woodsafe Timber Protection AB is an industrial manufacturer with certified authority to refine and place wood products with fire-resistant properties for use as building materials, both exterior and interior according to European Building Products Regulation 305/2011, as well as national building regulations. The business is conducted in a factory just outside Västerås, where, in collaboration with partners, we refine various types of wood for distribution to, among others, Sweden, Norway, Denmark, Holland, Belgium, France, Greenland, Iceland, Great Britain, Ireland and New Zealand.

Woodsafe Timber Protection AB's unique technology means a refinement of the wood's natural properties when exposed to fire, and maintains the highest requirements for combustible material. The type of wood itself that is treated is in symbiosis with the fire impregnation that achieves the fire classification SP FIRE 105, Euroclass B-s1,d0 or -s2, depending on the type of wood and installation conditions.

Since 2009, the products have been CE-certified according to CPR305/2011 (CPD 89/106) and nationally type-approved since 2008. We are certified by a notified accredited body (RISE, 0402) for our systematic quality and management system according to ISO 9001:2015, as well as environmental work according to 14001:2015. Our business is 100 percent dedicated to fire impregnation, which means security for downstream users.

"Our processes create an opportunity for the client to commission the architect to design wooden buildings, where expert fire consultants have their fire technical requirements met via our certified products. In the procurement stage, access is available through our partners in the wood industry, which is seamlessly handled in a value chain to be delivered to the contractor's workplace which is handed over to the client and family. One call and the circle is closed”

Featured projects in 2021

WOODSAFE® fire impregnation

Ilulissat Icefjord Centre

On the west coast of Greenland lies the massive glacier Sermeq Kujalleq.

For more than 250 years, glaciologists have studied the ancient glacier and its daily production of enormous amounts of ice, and it remains an ideal site for scientific observation of climate change. The Icefjord Center will tell a story about ice, about human history and evolution on both a local and global scale. Interior oak paneling adorns this stunning building which has been fireproofed with WOODSAFE® PRO.™

Universeum

Universeum's world-unique visualization lab and visualization dome.

The world's first public visualization lab, Universeum, gets a new wooden dome, designed by Gert Wingårdh. The spherical dome will consist of 6 meter long and 8 meter high triangular facets, which together with the built-in roof terrace will house the world's first public visualization lab. The facade consists of cedar shavings that have been fire-impregnated with WOODSAFE® Exterior WFX™.

Kilströmskaj

In the world heritage city of Karlskrona, forest and sea meet.

The World Heritage City is built on islands in the middle of the Blekinge archipelago. On one of these islands, right next to the Saltö Bridge, around 40 new apartments are being built with generous sea views in several directions. There will be three unique wooden buildings that borrow details from Karlskrona's landmarks and at the same time form a new public place with green slopes down to the water. The facade consists of cedar shavings dyed in red, black and silver gray shades, impregnated with WOODSAFE® Exerior WFX™.

The cedar houses

The world's largest wooden house project in an inner city environment.

The project contains four buildings in two blocks, with a total of 234 apartments and 8 rooms. The cedar houses will be built with a solid wooden frame (7 300 m3), with the exception of the two lower floors, which are made of concrete to distribute the loads correctly in relation to the foundation conditions. The project's four towers, 10-13 storeys high, form a wide front to the south towards Norra Stationsparken. Wooden facade consists of cedar shavings, yellow and red impregnated with WOODSAFE® Exerior WFX™.

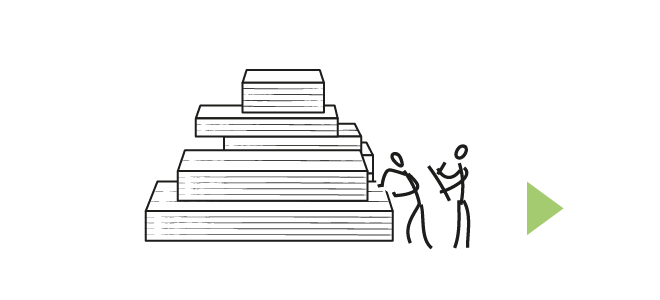

100+ checkpoints

Quality chain

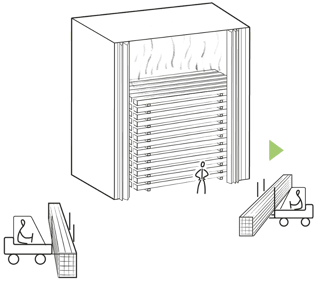

Arrival control & registration in WQS

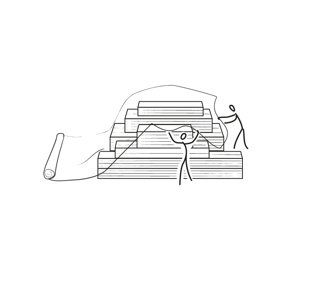

Unwrapping & labeling of packages

Mechanical handling of timber when stacking packages up and down

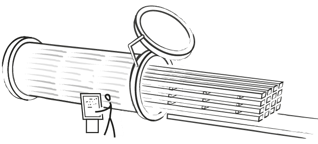

Vacuum pressure impregnation process linked to wood type & fire class

Drying and fixing of fire retardants in special drying chambers

Quality control & packaging before delivery to workplace

Finished fire-impregnated wood product

WOODSAFE® PRO™ or WOODSAFE® Exterior WFX™